Most people involved in projects agree that it’s a good idea to monitor the quality of the project. Of course. Who could argue against it? Would anybody really oppose a job well done? The difficulty lies in how to measure project ‘quality’. On this topic, it is not so easy to agree.

Quality Management, as studied today, has its roots in the manufacturing environment. Given this background, the accepted definition for quality has become “to prove conformance to requirements”. For a manufactured product to claim high quality, it must conform to a whole series of tests, measures and specifications. Similarly, that is what quality in the project environment should try to prove: that the products or services delivered by the project are fit for use and fulfill the requirements for which the project was undertaken. There are two broad steps we suggest here so that, regardless of the content of your project, you can instill Quality into the project’s results: (1) Design measures relevant to the project and (2) Take and analyze these measures.

1. Design Quality Measures

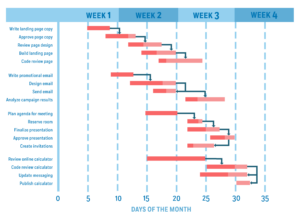

It is a good idea to have this activity as the last step in breaking down & planning the project’s workload. As we are discussing the steps and tasks which the different project resources will need to perform for a given deliverable, it is good to keep asking “And how can I prove this work is finished?” “And how do we know that item is ready for use?” The answers to these questions can then become part of our quality measures.

We should aim to make these quality measures as quick and as unobtrusive as possible. For example: instead of having a team of experts fly across the country to test a set of installation instructions, we can have someone unrelated to the project, but local, try to follow these instructions. This option is faster and cheaper. Which highlights another good goal for our quality measures: they must be affordable and totally defensible when being presented to the project sponsor.

Another recommendation is to have many intermediate, quality ‘mini-reviews’ instead of a large quality test at the end of a phase. More things could go wrong if we wait to have a large, final quality review attended by many stakeholders. If we have kept quality tests more frequent and limited, we can have more confidence on the final work product.

2. Take And Analyze The Measures

After agreeing which relevant quality measures will be taken during the project, we need to –of course– take them. Once the results are back, we want to put in place any corrective action needed, but we also want to analyze the results and see what else can they tell us. Unfavorable quality results may mean there is someone in the project team that needs more training. Or that there are some tasks for which the time estimates were wrong. By studying the results we will be able to enact that most important activity in projects: continuous process improvement.

—————————

For more resources, see the Library topic Project Management.

—————————

Sections of this topic

Sections of this topic